|

Volvo

|

1926

- |

Country: |

|

|

Assar Gabrielsson and Gustaf Larson

Scandinavia’s largest industrial undertaking was born over a dish of crayfish in a Stockholm restaurant in 1924. Two Swedish engineers, Assar Gabrielsson and Gustaf Larson, who had been colleagues in the big SKF ball-bearing firm, decided over their seafood meal that Sweden ought to have a car industry. Larson had worked for some years in the British car industry, and was able to contribute design. Gabrielsson, sales manager at SKF, had management expertise to offer. An artist named Helmer Mas-Olle tackled styling. All they needed was money.

Even without financial backing the team pooled their resources to produce a series of ten prototypes, the first of which was ready by June 1926 and promptly made a successful run from Stockholm to Gothenburg. This effort attracted the attention of SKF, who soon decided to back these pioneers. SKF even had a small subsidiary company which they handed over as a ready-made manufacturing concern. It was called Volvo-based on the Latin for 'I roll', a reference to rolled steel.

The Volvo Jacob BV4

Gabrielsson and Larson became the chief executives, and Volvo was in business to manufacture cars. From the start it was decided to utilise the capacity of the Swedish engineering industry, with the manufacture of components by various Swedish companies and assembly by Volvo at Gothenburg. It was a modest enough beginning - a mere ten workers assembled the first model, nicknamed Jacob. On 14 April 1927, model BV4, was completed, with an open sheet-steel body on a frame of ash and red beech, and a four-cylinder side-valve 1944 cc engine giving 28 bhp and a top speed of 48 mph.

After an embarrassing technical hitch whereby the car would run only in reverse gear, the Jacob rolled out of the factory gate. In all 205 were built. The following year another version appeared, the PV 4, with the same chassis and running gear but with a closed wooden leatherette-clad body. In 1928 a 'Special' was added, with a fuller specification. It drew attention to Volvo internationally by winning its class in a Moscow-Leningrad-Moscow speed, economy and reliability trial. It was well built and sold steadily, taking total Volvo production into four figures.

In 1929 a six-cylinder car was produced, the PV650, with a 68 mph capability from its 55 bhp 3010 cc engine. It soon went into PV651 and 652 series with hydraulic brakes and a synchronised gearbox. Production of this car displaced the earlier four-cylinder models and 2400 were made. A TR670 wooden-frame model, and similar TR671-674 models but with seven-seater taxi bodies, were added to the range, which was produced until 1934, some 600 being built.

During the 1930s Volvo evolved a series of solid family cars somewhat similar in appearance to the American cars of the period. The PV653 and 654 saloons and PV655 luxury version with wooden frame, two spare wheels and automatic reversing lights were produced in 1933 and 1934. These models offered five seats and were powered by a 65 bhp 3266 cc six-cylinder side-valve engine driving through a three-speed gearbox with freewheel facility. Ever mindful of the working nature of the motor car Volvo followed on with three taxi versions of this car, the TR676, TR678 and TR679 models, with two occasional seats between front and rear seats extending the seating capacity to seven. TR675 and TR677 models of the same series were separate-frame prototypes of which only a couple were built in 1934.

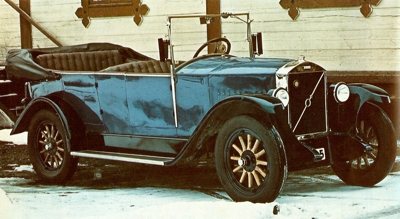

1928 Volvo OV4, which featured a 1944cc four-cylinder engine.

Another image of the Volvo OV4. The body was sheet-metal formed over an ash and red beach frame. The first cars were nicknamed Jacob.

1931 Volvo PV650, which was fitted with a 3 liter six-cylinder engine.

The Volvo six-cylinder PV60 was first seen in 1942, but was not put into production until 1946. Considered as one of the first 'Americanised' European cars, it was fitted with a three-speed gearbox with optional overdrive.

The Volvo PV444 was successful in the US market, and went a long way to establishing Volvo outside of Sweden.

The Volvo PV444 developed an International reputation for solid quality construction and good manners.

The Volvo PV445 was the wagon version, and also proved very popular.

The Volvo PV544 proved incredibly popular, and 440,000 were manufactured between 1958 and 1965. It was based on the PV444.

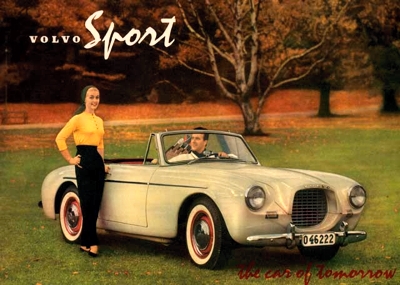

1956 Volvo P1900, an open sports car with glass-fibre body fitted with a 70 bhp version of the PV 1414 cc engine, and capable of 108 mph.

1956 Volvo P1900 was intended for export only, though a few were sold in Sweden. Only 67 were built.

The Volvo Amazon was manufactured from 1956 to 1970, and introduced in the USA,as the 122S at the New York International Auto Show in April 1959.

The Volvo Amazon quickly developed a reputation for being indestructable - a car that was built to last.

The Volvo Amazon Sport.

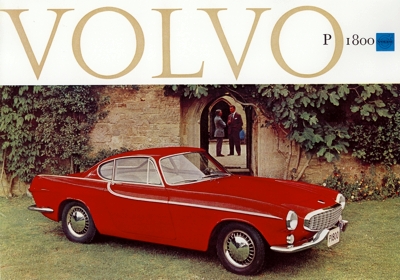

1964 Volvo P1800S.

1964 Volvo P1800S. The bodies were built for Volvo by Jensen at West Bromwich, UK.

1964 Volvo P1800S.

1964 Volvo P1800S.

The Volvo 120 was also very popular in wagon form.

1970 saw the last model year of the Amazon/120. By then it had a 2 liter engine but had successively been replaced in the model programme by the more modern 142 and 144 Volvos.

Volvo 142 lifts a wheel during the Swedish Rally.

1973 Volvo VESC (Volvo Experimental Safety Car) - a rolling laboratory for the testing of safety systems.

1974 Volvo 244DL.

|

A steady rounding of the body style was in evidence with the return to the PV series in 1935. The PV658 and 659 saloons were based on the previous PV cars but .had a bigger six-cylinder unit displacing 3670 cc and producing 80/84 bhp. The bonnet was lengthening now and the radiator inclined slightly rearwards. The total appearance was similar to the Chrysler Airflow model of the same time. Production of these five-seaters continued until 1937, more than 400 being made. As usual, taxis were also based on these models, with three versions produced. All had seven-seater bodies and more than 900 were built-further evidence that Volvo favored the business user rather than the private owner. A run of separate-framed TR702 models to order during these two years totalled only eleven cars.

The Volvo Carioca

The emphasis changed in the mid-thirties however. Having assuaged the taxi market with its Big Sixes, Volvo settled with the 3670 cc engine for an extensive series of PV models which carried the firm up to, through and beyond World War 2. It began with the PV36 of 1935 - Volvo's first streamlined model with faired-in headlamps, known as the Carioca. It had a steel body, excellent comfort levels, and featured independent front suspension; in all, 500 Cariocas were built. It was followed in 1936 by PV51 and PV52, which stepped back a bit by having separate headlamps. Its spaciousness, good road-holding and economy made it Sweden's most popular car, and about 3000 were produced between 1936 and 1938.

Two larger wheelbase taxi models with eight-seater bodies (including three occasional seats) and up to 86 bhp output from the same engine were brought out in 1938. More than 1600 of these were built up to 1947. Despite their size they handled easily and remained a familiar sight on Sweden's streets until the late 1950s. Volvo was one of the very few car makers able to think in terms of new models during the early 1940s, and in 1942 devised a new six-seater saloon, the PV60, using the same engine and three-speed transmission but with the innovation of optional overdrive. Five of these cars were built in 1942, the car was publicly announced two years later, and production commenced in 1946, continuing until 1950. Just over 3000 were built.

This was the last of the 'Americanised' Volvos, and also the last six-cylinder Volvo until 1968. The version of the 3670 cc engine installed in this car, which produced 90 bhp, was also used in the first Volvo post-war taxis, the PV821 and 822 models of 1947 and 1948. The frontal treatment of these departed from the separate headlamp style, with a strong horizontal grille treatment linking the front wings and the headlamps placed well in from the corners of the car to protect them from incidental damage. About 500 of these cars were built, and at the time Sweden regarded them as the perfect taxi.

The Volvo PV444

A further 1100 autos in another series, the PV831 and 832 used the same body and components but with some refinements were produced from 1950 to 1957. From 1950 to 1958 two related saloons sharing the same body and running gear were produced, more than 2000 of which went to private owners. But as far back as 1944 Volvo management had looked ahead to a post-war demand for smaller and more economical cars, and developed a small saloon with a 1414 cc overhead valve four-cylinder engine developing 44 bhp. This PV444 model, with a two-door integral steel body, independent front suspension, coil rear suspension, three-speed gearbox and hydraulic brakes was the first Volvo to sell in any quantity outside Scandinavia, and it rapidly established for Volvo an international reputation for solid quality construction and good manners.

The basic PV 444 design remained in production for fourteen years, though eight substantial series of improvements were rendered, including one up-rating of power output from 44 to 51 bhp and, finally, the enlargement of engine capacity to 1583 cc and the output to 60 bhp. Altogether the PV444 production totalled 196,000 up to 1958. From 1953 to 1960 a related PV445 in a total of 22 versions was also produced, although in much smaller numbers. These included a number of pick-up and van versions.

The Volvo P1900 Sports

Volvo tried a brief departure from the serious working-car approach in 1956/7 in the form of the P1900, an open sports car with glass-fibre body fitted with a 70 bhp version of the PV 1414 cc engine, and capable of 108 mph. This car was intended for export only, though a few were sold in Sweden. Only 67 were built. In 1958 everyone thought Volvo were going to drop the long-running PV444 design - but they did so only in favour of a revised car, the PV544, which bore a close family resemblance to the 444.

In the seven years of its life it had seven revisions. For the first three years it was powered by a 76 bhp version of the 1583 cc engine, then this unit was up-rated further to 1778 cc and 90 bhp. In its final two-door PV544 form this engine gave 95 bhp. When production ceased in 1965, 440,000 had been produced. Over the same period five versions of a 544-based van or wagon, the Duett 210, were produced, firstly with a separate chassis framework and later with an integral steel body.

After the end of 544 production the Duett continued until 1969, and a total of 61,000 of these vehicles were produced between 1960 and 1969. Overlapping with the best-selling PV544 series, a new and more modern large sedan was developed, starting in 1956 with the P1200, a four-door sedan with a vertically split grille and a broad-shouldered body style that carried the Volvo badge into new niarket areas. Powered by the proven 1583 cc 444 engine putting out 60 bhp, it was marketed as the 120.

Nearly 13,000 of these were made, and in 1958 came modifications which resulted in 121 and 122 versions. Over the period from 1956 to 1966 no fewer than seventeen versions with this body-shell were produced, including up-ratings of the 1583 cc engine to give 85 bhp, and the adoption in 1961 of the previous 1778 cc engine of the 544 which was still in production for the home market at that time. A two-door P130 version was added in 1961 and ran through to 1970, embracing in 1968 a further increase in engine size to 1986 cc and an output of 118 bhp. A total of 564,000 of this important series were produced.

Volvo and Safety

During this time the wagon version was virtually unchallenged in Europe in its market sector, and it became a firm favorite with doctors and other professional people, and earned Volvo a massive reputation as the producer of tough, reliable and long-lasting cars. The P220 estates appeared in 1962. They underwent seven sets of modification - improvement was an annual affair at Volvo - and a total of 72,000 were produced up to 1969.

While the 120/121/122/130 sedans and 220 wagons were putting Volvo into the big league, however, they were also establishing something else- Volvo's pre-occupation with car safety. In 1956 the 120 pioneered a safety steering column with shear coupling. Rear seat belt anchorages followed in 1958, and front seat belts became a production-line fitting in 1959. In 1962 Volvo was fitting large-diameter disc brakes on all four wheels. A brake servo and pressure limiting valve on the rear brakes to prevent locking up and skidding were added in 1965.

The firm also acquired a reputation for thinking of the customer's backs - the seating, from 1964, was highly adjustable and orthopedically correct. Though the 120/130 series soldiered on until 1970, in 1966 a totally new body appeared - the 144 four-door, supplemented the following year by the 142 two-door and the 145 estate. These models in their various forms were powered by 1773 cc or 1986 cc versions of the well-tried four-cylinder unit.

It was in Volvo's approach to their construction that they were most significant, however. Notable was the body construction - impact-absorbing front and rear compartments developed with the use of crash-testing, and a near crush-proof passenger compartment incorporating a roll-over bar in the roof structure, and anti-burst door locks. This great body strength was only one half of the story, as Volvo also devised a dual-circuit failsafe braking system-discs all round with a double split-triangle system, each linking both front wheel brakes with one rear.

These, and several other detail safety features such as a new telescopic steering column (anticipated for the coming legislation) marked Volvo as showing the way whereby logic could and should be applied to car construction rather than allow the old conventions and attitudes to continue. This approach was to become more and more important as critics of the motor car in general turned on the car makers and accused them of anti-social attitudes, and even of negligence and carelessness with the safety of their customers. More than this - further improvements introduced by Volvo, such as front head restraints and a heated rear screen as standard equipment in 1969 and rear window wash-wipe in the 1970 wagon, pointed the way eventually followed by every car manufacturer.

These innovations demonstrated that so-called luxury items on expensive cars were not luxuries at all but important features affecting the driving safety of every motorist and by no means the prerogative of the wealthy. The 142/144/145 series of four-cylinder cars which set the seal on Volvo's total involvement with safety was joined in 1968 by the 164, the firm's first six-cylinder car since the PB60. With leather upholstery and automatic seat-belts among its standard fitments the 164 rapidly became the top-selling six-cylinder car in its home market, and did well in export markets too, again benefitting from Volvo's increasing stature as a builder of enormously strong and safe cars.

The Volvo P1800

Again there was an annual revision, and up to 1974 production of the 2978 cc 164 had totalled 134,000. Though the 142/ 144/ 145 four-cylinder range was replaced in 1974, the 164 remained successful in the market place. While the 120 series was thriving through the 1960s, Volvo again tried its hand at a sports car, and the fixed-head GT two-seater P1800 was announced in 1961, utilising the same 1778 cc unit firstly in its 100 bhp form, and later in 108 and 115 bhp forms. This engine was also employed briefly at the time by Facel Vega and Marcos.

The P1800 bodies were built for Volvo by Jensen at West Bromwich, UK. Some 28,000 of these were produced up to 1968, when the 1986 cc unit was fitted, firstly in 118 bhp tune and then in 130 and finally 135 bhp form. Another 10,000 of this model were produced with these engines before the model was discontinued in 1972. From 1971 to 1973 a sporting 1800 in the Reliant GTE manner was produced, using the 135 bhp engine. More than 8000 were built.

Volvo's commitment to greater structural integrity and safety design in cars crystallised in 1969, when the firm established its own criteria for an experimental safety vehicle. A fleet of ten of these 'rolling safety laboratories' were built. These were to be no theoretical vehicles, however. While the American safety vehicle requirements published in 1970 (and surprisingly similar to Volvo's own list) resulted in a number of armoured and overweight vehicles which would have smashed anything they nudged and guzzled fuel whenever they turned a wheel, Volvo were aiming for practical application of the results of their experiment.

The Volvo Experimental Safety Vehicles

The Volvo ESVs (experimental safety vehicles) combined all that Volvo had so far devised and incorporated into the 144 series, with other safety design already planned for the next series. The result was one large safety project that related to existing Volvo cars, and was therefore at the same time a production project. Different ESV's in the fleet featured different ideas, but the definitive vehicle added something like a score of positive safety improvements to the already well-wrought 144 structure. More than 40 inches of deformation were designed in for frontal crashes of up to 50 mph. Front and rear bumpers were rubber faced, the ends sheathed in moulded plastic to prevent their hooking into anything, and mounted on telescoping shock absorbers so that the front bumper would flex seven inches in a 10 mph bump and the rear 3½ inches.

The grille sloped to deflect any unfortunate person struck by the front of the car. The headlamps were well sunk, and provided with a wash and wiper system. Brakes, discs all round, were fitted with an electronically controlled anti-lock system, and radial ply tyres were fitted for longer life and better roadholding. The rear suspension had a self-levelling system. The windscreen-wipers were recessed so that a pedestrian flung on to the bonnet by the sloping grille would not be torn by the wiper arms. Hooked door-lock units the 200 series, incorporating basically the same telescopic bumper and frontal deformation principles perfected in the experimental cars, met at 40mph the US requirements for a 30 mph frontal collision, though the 40 mph crash created almost double the kinetic energy as the 30mph one.

The World's First Production Safety Vehicles

This characteristic alone reduced the stresses on occupants by twenty per cent compared with the 140 cars. Further innovations came in 1975 - most notably 'day-notice' lights which came on automatically with the ignition and stayed on to help other traffic perceive the car's approach: a stepped-bore master-cylinder giving almost full braking effect without increased pedal load with one brake cylinder out of operation: and rear seat belts as standard. The sum total of these safety characteristics, the need for many of which Volvo identified as much by accident analysis as by its own controlled experiments, has led the firm to claim that the 200 series cars were the world's first PSV's - production safety vehicles.

Many authorities would not dispute the claim - the day-notice lights and stepped-bore master cylinder won the Swedish AA Gold Medal in 1975, Spain gave the 200 series the Velocidad award for its safety provisions, an Italian Gold Medal was awarded as a result of a readers' poll in fourteen daily newspapers to find the car maker with the best reputation for products and services, a leading Norwegian magazine chose the 244 as Car of the Year for its safety, life-expectancy and trade-in value, and America's top motoring magazine chose the 244 as the best family car in all categories in competition with 45 other models.

In 1978 Volvo face-lifted their range, and gave the engines of both the 240 and 260 range higher compression ratios, raising output by around 8 bhp. In the late 1970s Volvo seemed firmly wedded to their collection of expensive and substantial, and of course very safe, cars, but this was meeting with some resistance from consumers, and Volvo's share of many export markets declined in 1977. A new small Volvo was added to the range this year - the 66GL, based on the then current DAF sedan and wagon and powered by a Renault 1300 engine, but with the interior redesigned by Fiore and a radical revision were installed to prevent doors bursting open in a crash.

In any type of collision at least two doors were designed to remain openable to allow rescuers into the car. A protective side moulding ran all the way round the bodywork to guard against incidental bodywork damage. Tubular reinforcement members were mounted laterally inside the doors to minimise the risk of intrusion by another vehicle hitting the side of the car - no more than four inches intrusion from another 30 mph vehicle. Doubled steel members were built into the window pillars and a doubled steel rollover bar was incorporated into the roof. In all types of accident the entire fuel system was designed to remain intact, with a deceleration-activated cut-out fuel pump positioned towards the rear to minimise the risk of petrol spillage and fire.

Fire retardant materials were specified for the interior. The interior was also stripped of all protrusions and padding was employed generously. Automatic three-point seat belts were installed. Head restraints popped up on the front seats in a collision. The backs of the front seats were thickly padded to minimise the risk of injury to rear passengers flung forwards in an impact. Rear seat head restraints were installed. The feel of the car was lightened and made more sensitive than in the weighty 144 series, and a spring-loaded steering wheel was fitted so that in the event of a frontal crash the steering wheel was instantly jerked six inches forward to the facia and at the same time away from the driver.

In some Volvo ESV's air bags were installed. Others had door-mounted seat belts, and others a semi-passive design which came into operation automatically when the car was started and the handbrake released. Various systems were tried to ensure that a disproportionately heavy load in the rear did not cause the headlamp alignment to dazzle oncoming traffic. And all the ESV's featured four-cylinder fuel-injection engines equipped with exhaust gas recirculation systems and catalytic converters for maximum pollution control.

The Volvo 242, 244 and 245

Volvo was not the only car maker experimenting with safety at this time, but the firm certainly took things further earlier than any other European manufacturer, and the strictly practical attitude to its findings found expression in 1974 with the appearance of the 144 series replacements - the 242 two-door sedan, the 244 four-door, the 245 wagon and the 264 four-door. The 242/244/245 were powered by a new four-cylinder 2127cc engine with crossflow aluminum allow cylinder head and belt-driven overhead camshaft. This engine appeared in two forms: with 8.5 to 1 compression ratio giving 97 bhp at 5000rpm, and with 9.3 to 1 compression ratio producing 123 bhp at 5750rpm; both accepted economical 93 octane petrol.

The 264 was fitted with a new 90-degree V6 unit displacing 2664cc, with aluminum alloy engine block with wet liners, aluminum cylinder heads, and a chain-driven overhead camshaft between the valves on each bank. Ignition was of the transistorised breakerless type, and the fuel system continuous-injection, these systems allowing a high standard of emission control with settings remaining accurate over a long period. This engine also used 93 octane fuel. Output was 140 bhp at 6000 rpm with a compression ratio of 8.7 to 1. But while Volvo had moved into a new generation of engines, they also utilised the knowledge which their ESV programme produced.

In 1974, and 1975 Volvo bought a controlling interest in the DAF car operation and established its own operation, Volvo Car BV, at Eindhoven, so resolving the firm's long-standing intention of getting into the smaller car market segment, though the DAF had been used as a basis for the first model. Meanwhile the Volvo 66 brought to the DAF-based two-door profile the familiar Volvo preoccupation with safety - telescopic steering shaft, inertia belts front and rear, front seat head restraints, split brake circuits, high-impact laminated screen, and rubber-faced bumpers. The overhead-valve engine produced 57 bhp at 5200 rpm. Brakes were power-assisted, the fronts being discs. The DAF De Dion rear axle was retained.

Pehr Gyllenhammar

The next car from Volvo's Dutch operation was the 343 introduced in 1977, This was larger than the 66, and not dissimilar from the Volvo Experimental Safety Car of 1973 in appearance, but it used the old DAF continuously variable transmission, and a 1397 cc four-cylinder engine, The next year Volvo offered the 343 with a manual gearbox option, however, in addition to the automatic transmission. By that time Volvo's car assembly plant at Kalmar had become a landmark in the use of technology to eliminate assembly lines as such and to increase the job-satisfaction of the employees.

Kalmar grew in the early 1970's out of a joint project by management under the newly-appointed managing director Pehr Gyllenhammar and labour representatives from all levels, They had as a working brief the experiences of Volvo at various of its other plants where ongoing efforts had been made to achieve a better working environment for employer and employee. The result at Kalmar was a new approach on both technical and social levels. The atmosphere of a small workshop was achieved by sub-dividing assembly into twenty-five separate team operations, each group consisting of about fifteen people, with further subdivision into groups of two or three for certain types of job.

The transport of bodies was on separate battery-driven assembly carriers, not production lines, so that greater freedom in work planning was possible. In consultation with the foreman and production engineer the workers themselves suggested the working plan and division of responsibility for various operations, and job rotation was a feature of work patterns. In addition to assembly work, the workers were also responsible for materials supplies in their own team area and they played a part in continuous quality inspection. Work rates and breaks were varied to suit team and individual needs and wishes.

Core of the system was the assembly carrier, devised by Volvo, and controlled through electrical impulses from cables concealed in the floor. As well as a transport unit and working platform for the bodies during assembly (it could turn the bodies through 90 degrees on to their sides for easier working), the carrier also functioned as a transmitter of information to the factory's four computers which controlled overall production and monitored quality. Volvo safety design even played a part in these carriers - they had spring-loaded bumpers sensitive to a collision, and would stop from maximum speed within eight centimeters.

The Skovda Engine Plant

Volvo later tackled engine assembly in the same way, and in 1974 opened a new engine plant at Skovda employing groups of workers and assembly carriers instead of line assembly. Highly mechanised handling and electronic control of machining meant that women wereable to participate in what had previously been traditionally laborious engine shops. Perhaps a first for affirmative action in the motor industry, women were intended to have about forty per cent of the 1000 jobs - although we do not have any figures to ascertain if this was actually met, or exceeded.

At the start of 1977 it was thought that Sweden's two large car manufacturers, Saab and Volvo, would merge. The idea was considered strange by many who could not see the advantage for Saab in the proposed merger; their 99 series cars were establishing a good reputation, and the company was increasingly being regarded as a go-ahead innovative concern, helped by products like the Saab Turbo. Volvo, on the other hand, seemed to be going down something of a dead-end with the 200 series. In fact, the merger never materialised and Volvo's next step, after the Swedish government had refused them a multi-million development loan, was to sell forty per cent of their shares on the Norwegian stock exchange.

The arrangement was that the Norwegian government bought the majority of the shares in return for oil exploration rights in the North Sea - a strange arrangement, but Volvo did have a new petroleum division which could either use or sell the rights. In addition, the Norwegian government expected to have some new Volvo manufacturing plant constructed in Norway, to produce Volvo marine engines and a small 'city car'. Once again, however, many critics thought the whole plan unsound; labour, for example, was even more expensive in Norway than in Sweden.

Ford Motor Company's Premier Automotive Group

Volvo became part of the Ford Motor Company's Premier Automotive Group (PAG) on January 28, 1999. After the aquisition, Volvo set about creating a wider range of models - probably because Volvo was the only brand left in the group following the sale of Jaguar, Aston Martin and Land Rover. Ford decided to restructure plans for Volvo Cars, pushing it further upmarket alongside the lower end of Mercedes and BMW sedans, wagons, and SUV crossovers. The outcome was the luxurious second generation Volvo S80 and the new small premium crossover Volvo XC60.

Talks were held about the fate of Volvo Cars in the event of failure of US automakers, including Volvo's parent Ford. Swedish concerns mounted after repeated mass layoffs at Volvo, prompting Sweden to enter the spotlight to help its automotive industry. The government was asked to look into a possible state ownership of Volvo, or financial bailout for Volvo Cars and SAAB of GM. Eventually, AB Volvo responded to heated talks and decided that they did not want to see Volvo Cars fail, so they agreed to help Volvo cut costs through partnerships and even a possible share ownership amongst a larger consortium. AB Volvo repeated and stood stern that they will would buy back Volvo cars nor be sole majority owner. They were only willing to become part share owner of their erstwhile car unit.

Ford announced in December 2008 that it was considering selling Volvo Cars with an asking price of US$6 billion. The Swedish government was interested in helping with a possible Swedish acquisition, and it is believed that BMW AG of Germany, Investor AB of Sweden, Chinese investors, or Russian investors were all possible candidates for the purchase. Ford ultimately chose Geely Holding Group - although Geely had initially denied the plan, as did both Ford and Volvo.

Safety milestones:

- 1944 Safety cage

- 1944 Laminated windscreen

- 1954 Defroster vents for windscreen

- 1956 Windscreen washers

- 1957 Anchor points for 2–point safety belts front

- 1958 Anchor points for 2–point safety belts rear

- 1959 3–point front safety belts standard

- 1960 Padded instrument panel

- 1964 First rearward–facing child safety seat prototype tested

- 1966 Crumple zones front and rear

- 1966 Safety door–locks

- 1967 Safety belt rear seats

- 1969 Inertia reel safety belts

- 1971 Reminder safety belt

- 1972 3–point safety belts – rear

- 1972 Rearward–facing child safety seat

- 1972 Childproof locks on rear doors

- 1974 Multistage impact absorbing steering column

- 1974 Bulb integrity sensor

- 1975 Braking system with stepped bore master cylinder

- 1978 Child safety booster cushion

- 1982 "Anti–submarining" protection

- 1986 Three–point safety belt centre rear seat

- 1990 Integrated child safety cushion in centre rear seat

- 1991 SIPS – Side Impact Protection System

- 1991 Automatic height adjusting safety belt

- 1992 Reinforced rear seats in estate models

- 1995 Integrated child safety cushion outer rear seats

- 1997 ROPS – Roll Over Protection System (C70)

- 1998 WHIPS – Whiplash Protection System

- 1998 IC – Inflatable Curtain

- 2001 SCC – Volvo Safety Concept Car

- 2002 RSC – Roll Stability Control

- 2003 New Front Structure called Volvo Intelligent Vehicle Architecture (VIVA, S40, V50)

- 2003 Rear seat belt reminders (in S40 and V50)

- 2003 IDIS – Intelligent Driver Information System (in S40 and V50)

- 2003 Inauguration of Volvo's Traffic Accident Research Team in Bangkok

- 2004 BLIS – Blind Spot Information System (in S40 and V50)

- 2005 Introduction of DMIC (Door Mounted Inflatable Curtain, new Volvo C70)

- 2006 PCC – Personal Car Communicator (S80)

- 2006 CWBS – Collision Warning with Brake Support (S80)

- 2007 PPB – Power Park Brake (S80)

- 2007 DAC – Driver Alert Control (V70, XC70)

- 2009 City Safety – Automatically stop car at speeds below 19 mph (31 km/h) if obstruction is detected in front of car (XC60)

- 2010 Pedestrian Detection with auto brake (New S60)

Also see: Volvo Car Reviews